New Frontiers in Ion Channel Drug Discovery: Merging Small Molecule Medicinal Chemistry Expertise with Electrophysiology Technology

This page describes the foundational technologies that support our expertise in small molecule and ion channel drug discovery, areas in which RaQualia Pharma excels. By leveraging a strong base of established technologies, developed and refined over the years, we continue to innovate. We are adopting cutting-edge advancements, such as laboratory automation systems, to stay ahead in the evolving landscape of drug discovery technology.

This system facilitates the automation of compound synthesis tasks, traditionally performed by medicinal chemists. It autonomously manages critical steps, including reagent weighing, synthesis reactions, work-up procedures, and crude product collection. When integrated with the CAP (Centralized Analysis & Purification) system, it significantly accelerates the study of structure-activity relationships. According to our internal metrics, this automated approach improves synthesis efficiency by approximately tenfold compared to traditional manual methods.

The CAP (Centralized Analysis & Purification) system simplifies the purification of chemically synthesized samples, including those containing impurities. It automates the complete process, from purification to weighing, dissolution, and dispensing. Our internal metrics indicate that this automated approach is about five times more efficient than traditional manual methods. The system is capable of producing 200 purity-certified liquid samples per week, which are ready for evaluation.

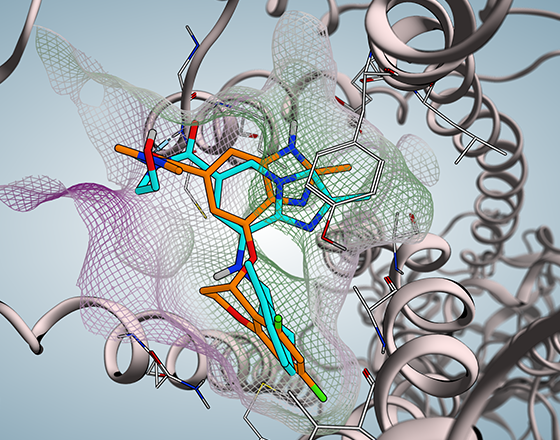

We analyze multi-dimensional data from our library of compound structures and their evaluations to accurately predict the pharmacology, pharmacokinetics, and safety profiles of potential compounds. This methodology facilitates the efficient design and synthesis of new compounds. Furthermore, we have recently adopted AI-based techniques for compound generation and virtual screening, further enhancing our drug discovery capabilities.

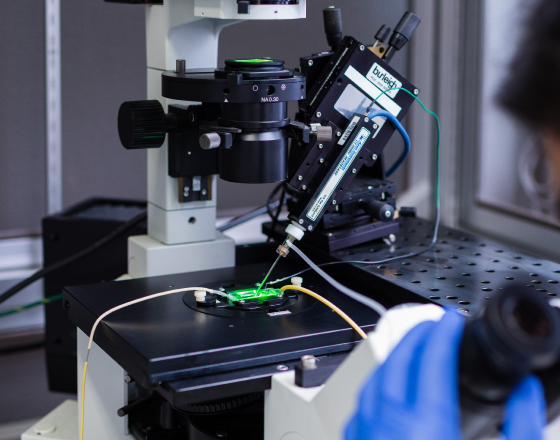

This technique is crucial for conducting electrophysiological experiments aimed at assessing ion channel function with precision at the single-cell level. Its successful execution requires a high degree of technical expertise and substantial practical experience.

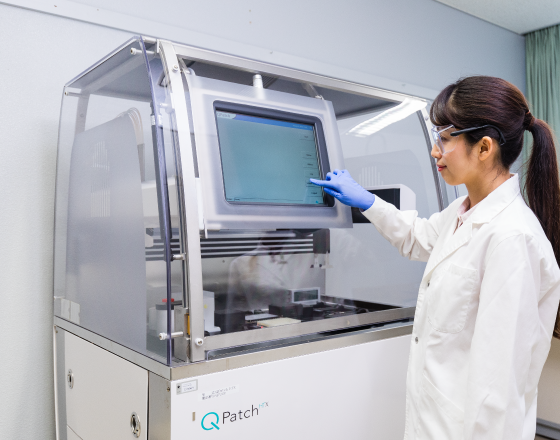

This system automates the traditionally manual patch clamp technique used for ion channel evaluation, achieving a level of precision comparable to manual methods. It significantly boosts efficiency by allowing for high-throughput screening (HTS) in electrophysiological assessments, thereby accelerating the evaluation process.

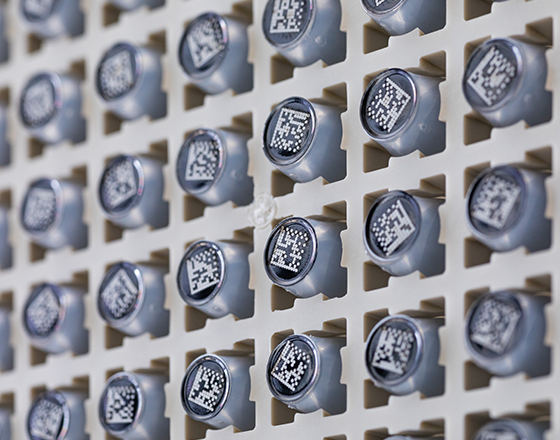

Compound data is meticulously organized using two-dimensional codes, which streamlines testing processes for pharmacology, safety, metabolism, and other internal studies. This approach ensures rapid and accurate data retrieval, and the results are promptly uploaded to the company's internal database for use in structure-activity relationship studies.

This instrument gauges extracellular potential in excitable cells, such as neurons, to assess the electrophysiological activity of neural networks. It employs a specialized plate embedded with microelectrodes, enabling cells to be cultured directly on its surface. This setup facilitates label-free, real-time monitoring of cell electrophysiological activities.

By integrating automated technologies, such as liquid handling systems and robotic arms, into our measurement instruments, we have streamlined various evaluation processes, substantially cutting the costs associated with high-throughput screening. We are committed to advancing automation to enhance the efficiency and precision of our sample evaluation processes, utilizing a select team of talented individuals. Working closely with engineers from equipment manufacturing companies, we have developed a customized automation system tailored to meet our specific requirements.

Learn more about the diverse drug candidates developed through the core technologies at RaQualia Pharma.